The Stamper

From the Hollander beater to the stamper

- from the inside, thanks to my longstanding work on pulps and their components: I analyse the papermaking process in its entirety, from raw materials to the finished sheet.

- from the outside, thanks to the close analysis of thousands of sheets of pre-industrial paper. I manipulate and understand paper according to the way it has been preserved.

For the last twelve years, I have worked in close contact with the binding and restoration workshop of Nadine Dumain, situated at the Moulin du Verger. This has provided me with direct feedback on the product I have made. I have learnt more by making very fine adjustments to my papers in response to the precise demands of Nadine than by trying to imitate the purely aesthetic aspect of the papers I have examined myself. This process has resulted in the manufacture of 17th and 18th century facsimile board and forwarding papers [1] and very lightweight infill papers (from 30 to 40 gsm).

Previously I made paper from worn out linen and hemp textiles which corresponded to pre-nineteenth-century western papers. These sheets had aesthetic and handling qualities similar to older types of paper. By sacrificing a little bit of lookthrough (2) I was able to maintain a degree of fibre length. Nevertheless, for years André Le Prat kept telling me, « It’s great, Bréjoux, but the fibres are too short ».

Meeting Christopher Clarkson, upon Stuart Welsh’s initiative, gave a real opportunity for learning and exchange. Chris showed me a variety of multi-couched papers from 200 to 750 g/m2, which are strong and resistant, flexible and sturdy. These papers were used as covering papers for limp bindings, in the manner of limp vellum bindings, from the Italian Renaissance onwards.

Christopher Clarkson’s pressing demand that I supply him with this kind of cover paper convinced me that I had exhausted the possibilities of my Hollander beater method. Indeed, however I went about it, only the use of stampers would allow me to improve the quality of my pulp.

However, there was no reason to believe, except in my imagination, that I would be able to achieve a decent result. The decision was not risk-free for the following reasons:

- The cost: manufacturing a machine of this type from the plans to the finished article costs 30 000 euros.

- The lack of an existing set-up: retting is an indispensable part of the switch to stampers, and nobody has retted the quantity of fabrics required in the making of a pulp for a very long time. To my knowledge nobody has run a stamper with this type of raw material for over 150 years. I therefore had to place my trust in de Lalande [Bertrand J.-E, 1820] and in my instinct. Having said this, it seemed to me that a little time would make it possible to achieve a satisfactory result, especially if the objective was to produce cover papers with a heavy grammage which do not require a very thorough refining of the pulp. Maybe after a few years we would get close to the beautiful paper types of the Renaissance. The latter were thick, flexible and responsive, and offered a luminous, clear lookthrough. If people were able to do it in the past, why not us today ?

Assembling the stamper

Since the 17th century there have been some good descriptions of the different stampers [de La Lande J., 1762 ; Barrett T., 1989]. The publication, Les moulins à papier et les anciens papetiers d’Auvergne [Boithias J.-L et Mondin C., 1981] (no longer in circulation), provided the best source of information and some reliable plans. I wish to thank Claire Mondin for her kindness in allowing me to use her drawings.

I acquired the services of a carpenter specialized in the restoration of historical monuments to deal with the part which involved wood and wrought iron, then asked a stainless steel specialist to make the hammer heads and an electrician to deal with the motorization. The objective was to find technical solutions which were adapted to the structure and way of functioning of the beater, rather than to imitate a particular aesthetic or tradition. I allowed the specialists full latitude in the choice of wood essences used.

The pivot block, hammer guide, pivot block braces, hammer shafts and camshaft are made of oak, while the hammers are made from larch wood and the tubs from plane tree. The cams are made of service tree wood. The metal parts which do not come into permanent contact with water (links and iron hook to hold head in raised position) are made of wrought iron, while the tapered spikes and bedplates are stainless steel. The iron trip plates are made of teflon. I chose to cover the end of one of the two hammers with a metallic plate with parallel ridges, rather than using nails, as the former would be more efficient (although lapping would be longer). I did not know when making this choice that a similar recommendation was made by Duponty as early as 1746 when he spoke of a shoe which is one-piece with grooves [de La Lande, 1762], and that they had been tried out successfully in Etampes in 1749. The second hammer has a smooth shoe, for the final refining of the pulp.

Starting up

This machine should be worked by a single person. It is driven by an electric motor, coupled with a variator. Transmission is enabled by multigroove pulleys and three triangular belts. Rotation occurs at 16 revolutions per minute, which is roughly equivalent to one hammer drop per second with a syncopated cadence.

Starting up, after the resolution of certain mechanical problems relating to transmission - it is difficult for a small present-day motor to deal with the shakes engendered by the shock of the cams on the iron trip plates - was simple to an extent I would never have dreamed of. The behaviour of the pulp under the hammers perfectly fits the various descriptions made in the 18th century. When a hammer is raised, it creates a depression which draws in the pulp expelled by the drop of the neighbouring hammer. The disequilibrium brings about a circulation which is more or less rapid according to the dilution and which allows all of the pulp to be worked upon.

Maximum concentration allows us to work on 7 kg of material in the tubs and seems to me to be inferior by 15% to that which is described in the different texts of the 18th century. As the capacity of the tubs is identical, either I do not yet fully master the working of the stamper or those descriptions were the reflection of a certain degree of optimism regarding production capacities.

The drying lofts situated above the living quarters of the Moulin du verger were the only frost-resistant zones used for the en pages drying (sheets dried in stacks of 7 or 8 and pressed without felts) of the paper made each day. A simulation of a complete drying process did not enable me to accommodate the supposed output of the Moulin’s two vats. The drying surface which was lacking corresponds to the aforementioned 15%. The journal kept by Henri Villarmin [H. Villarmin, 1775-1810] shows that the concentrations could be very different according to the types of material, their condition and the desired result. The descriptions in this text are so precise and detailed that they make the perfect guide. Starting up was carried out in the presence of the trainees who were participating in the second stage of the paper-covered binding workshop which we organize with Christopher Clarkson (see « moulinduverger.com »).

From « pulp » to gelatine size paper.

Considering the total lack of running-in, meaning that each hammer works at about 30% of its capacity (its strike surface being not strictly parallel to the camshaft), and in spite of all the trial and error, setbacks and uncertainty involved in the discovery of the operation of the machine, the results were remarkable.

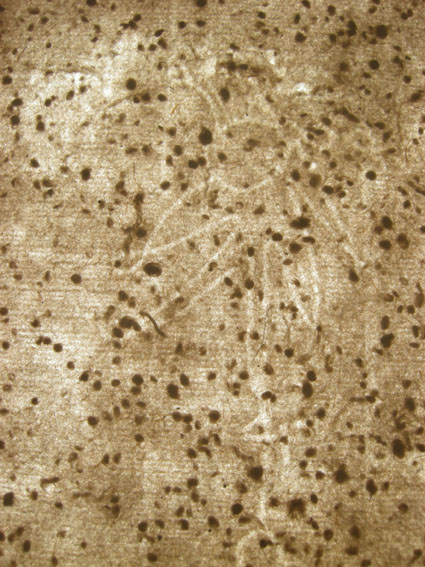

From the very first pulp, made of linen and hemp which had been fermented for several months (voir ill. 5), and despite the problems of heterogeneity one associates with such irregular materials, the lookthrough turned out to be unbelievably clear.

Everything led me to believe that the choices made had been the right ones, and that this machine was about to produce a pulp - « The Pulp » - I was expecting from it.

I never expected the changes to be so radical. The whole perception of the pulp making process is turned on its head, not least because we go from a duration of one or two hours with my Dutch beater (for 20kg) to several weeks with the stamper.

- Retting: this was a problem which preoccupied me for over two years before I found a solution adapted to my manner of production. The rags, torn up beforehand, ferment for several weeks (this duration is variable as it depends on the season). De La Lande’s description [de La Lande, 1762] is highly revealing. Nowadays retting is timidly referred to as fermentation. Industrial producers have come back to it in order to economize on the energy required in the refining of pulps. It is the only way of compensating for the growing fragility of shoes since the systematic use of rags in both the Middle East and the West.

- Stamping: this currently lasts a minimum of 25 to 35 hours (for 7 kg). During the first 10 hours of the process, washing by a change of the slushing water leads to a perfectly clean pulp (one which is far too white according to the restorers). Washing also provides the possibility, in case of a decision to dye the pulp, of eliminating unfixed pigments (I do not use mordant). The phenomenon of two-sidedness, due to the concentration of unfixed pigments on the mould side during drainage, is thereby eradicated .

- In the vat: behaviour during draining is completely different. It is difficult to work with water under 15 degrees, even with grammages inferior to 80 gsm. Without a doubt, the higher the temperature, the quicker the drainage.

- Couching: the behaviour of the wet paper is exceptional even before pressing and gives an indication as to how the Arabic Muslims managed to do without felt, although they did use rags as raw material. If drainage goes very well before couching, which is easier in the warm climes of southern Spain or the Middle East, it becomes possible to put wet sheets on top of each other and press them without them sticking, as long as they are not pressed too heavily. This seemed impossible before the experimentation with the stamper, and now provides an answer to a question I had been asking myself for years.

- The weight: the paper is thicker than its weight suggests: 60 gsm can feel like 75 gsm. The shorter the fibres, the more the sheet is compact and therefore slim in relation to its weight. I was receiving a lot of high-grammage orders. The most common order is for a 80 gsm sheet whereas the upper average rarely exceeded 70 gsm in the 17th century and tended to be even lower in the 18th century. However, this is only an average, and there are numerous exceptions, especially with manuscript papers [Bréjoux J., 2000]. Without wishing to exaggerate, we are not a million miles from the paper of the Far East, especially in the lower grammages. This reinforced my determination to make cover papers within a range of 30 to 50 gsm.

- The format: I realized a long time ago that that a large part of the production problems I encountered were related to format. Le Coquille, at 44 x 56 cm, is considered to be a large format which is better adapted to the manipulations of production than the Raisin (50 x 65 cm). Indeed, this format lessens the weight to be raised during the lifting of the sheet, simplifies couching and pressing and makes drying a lot easier. Smaller sheets are less liable to the phenomenon of air bells which are inevitable in a natural drying process (an essential stage of production which makes the dimensional stabilization of the paper possible). Furthermore, this format covers most needs, apart from a few rare exceptions which might be resolved by a specific form of production.

- Sizing: animal-tub sizing is pretty much unavoidable. It would be a shame to end a process which faithfully reproduces an old technique with a « modern » sizing. We would not even be sure of the subsequent reactions over a period of time. Furthermore, if we judge by the quality of the papers produced in the 15th and 16th centuries, gelatine, when correctly employed, has proved its worth. Animal-tub sizing of light papers requires pack-pressing and then en pages drying. Once pressed and lifted, the sheets are piled together and pressed again without felts in order to build the pack. The pack is separated into pages (6 or 7 sheets) which are put out to dry on the lines of the drying loft. These pages are soaked in a bath of gelatine then pressed to spread out and evacuate any surplus gelatine. It is certainly not possible (within normal criteria of production) to imagine such light sheets being soaked with glue and manipulated and pressed without this leading to their destruction [de La Lande, 1762]. The final racking for drying is carried out sheet by sheet.

- The finished product: even before animal-tub sizing, one obtains a totally unique type of paper. The work of the hammers gives the paper a greater flexibility and elasticity, as well as greater strength and resistance to tearing and folding. Experiments with rubbing result in a patina and a gloss which is similar to that of burnishing. This is due to the preservation of fibre length which the Hollander beater does not enable. We may also observe that similar comparisons were made in the 18th century between Dutch papers and other papers: the former, praised for their regularity and beauty, were criticized for their fragility.

Going beyond misleading interpretations

Why was this experiment not carried out earlier ? For half a century now, hand papermaking has been misinterpreted. There are countless stampers in existence, so the price of the machine cannot be an obstacle. Some of them are absolute gems, and all of them are exploited as educational attractions. It is easy to make an open-mouthed audience believe that you really use a stamper to make your pulp. The fact that it crossed nobody’s mind (with the exception of a small number of experiments carried out by Timothy Barrett) to fit them out with something other than that ersatz of paper pulp known as cotton linters and to make them really work on a material for which they were designed, says a lot about the interest which my western contemporaries show in materials, techniques and their history. It is vital, in order to understand how and why an unbelievable quantity of materials (I’m not just talking about paper) have spanned the centuries, to rediscover the essence of matter-of-fact, basic and utilitarian practice. It will always be easier to gloss over the texts and products than embark on an adventure which demands real know-how, entails a re-eavaluation of one’s own methods and which even risks going completely unnoticed.

Time is needed in order to understand the subtleties of processes which can only be carried out manually. The much lauded « savoir-faire » of the métiers d’art (the French term for the craft professions, which does not inherently recognize the importance of manual expertise) is in fact the result of millions of repeated gestures, the real benefit of this being the reflex actions acquired (exactly like the scales of learned by a musician). This is the truly irreplaceable kind of expertise. The Japanese understood this a long time ago. Somehow or other, they have maintained the existence of authentic crafts. This clearly seemed essential to them. The production of certain paper types which are adapted to their culture is necessary for restoration, for the presentation of their patrimony and for use by contemporary artists. However, let us not be fooled. Workshops are increasingly rare and are the victims of economic laws which seldom guarantee quality (90% of them have disappeared in half a century).

For us westerners, the earliness of our industrial revolution has radically cut us off from the old manufacturing techniques. In fact, the latter have completely disappeared from the landscape (except in inauthentic forms), so we are condemned to reconstructing everything from scratch.

The stamper gave me the awareness that my approach to hand-made paper was directly inherited from those 19th century techniques which have nothing to do with the earlier techniques. Manual production has survived because new methods adapted themselves to production techniques which were virtually non-existent in previous centuries. Just one look at the moulds, their format, the papers made, the felts used and the sizing allows us to observe that they have strictly nothing to do with whatever was produced before industrialization. In this context, the notion of artists’ paper should be the subject of a close study, which, to my knowledge, has never been envisaged from this angle.

We also need to persuade potential users (institutional or otherwise) about the merits of our approach, which can only really be criticized for actually being too simple, for requiring more know-how than technology, or for seeming backward, nostalgic and costly. This is a difficult task in a value system where the engagement of the body is totally undervalued (the term « Métiers d’Art » is used by the Ministère de la culture and suggests there are artists but no artisans). In fact,the whole basis of my approach lies in this challenge.

Having said this, I am delighted to join a long line of people who have demonstrated that there is an unquestionable link between a product and the technique used in its creation. Changing production to a meaningful scale is an essential stage of the process, one which saves us from getting lost in the over-interpretation of microphenomena. It is vain to pretend to be free of this constraint. A reality check remains the most convincing way of proving one’s worth. All the attempts made (my own included) to bypass technical constraint, by the use of substitute materials or, in some case, in appropriate means, have only led to unsatisfactory results (aesthetic considerations aside) compared with what it is possible to do.

I grew tired of waiting, so initially financed the project alone. Thereafter Jane Giscombe, Stuart Welsh and Marlène Margez all contributed as their resources would allow, and I thank them for it.

Jacques Bréjoux, Principal Papermaker of the Moulin du Verger, France

Many thanks to Nadine Dumain, Sébastien Gilot and Marlène Margez, who gave me great help with the intelligible formulation of ideas which seemed self-evident to me.

Notes :

[1] Forwarding: term used in binding to designate the operations carried out on the sheets before sewing, including repairs to the folds of double sheets and to tears as well as the assembly of the covers, inserts and end papers.

[2] Lookthrough: structural appearance of a sheet of paper observed when viewed by transmitted light.

Bibliography :

Barrett T., « Early European Papers / Contemporary Conservation Papers : A Report on Research Undertaken from Fall 1984 through Fall 1987 », The Paper Conservator, vol. 13, 1989, p. 57-65.

Bertrand J.-E., Art de faire le papier par M. de Lalande, nouvelle édition, augmentée de tout ce qui a été écrit de mieux sur ces matières en Allemagne, en Angleterre, en Suisse, en Italie, etc. Paris : J. Moronval, 1820, ? p.

Boithias J.-L., Mondin C., Les moulins à papier et les anciens papetiers d’Auvergne. Nonette : Créer, 1981, 266 p.

Bréjoux J., « Question de grammage ». www.moulinduverger.com, 2000.

de La Lande J., « Art de faire le papier ». In Les arts du papier. Genève : Slatkine Reprints, 1984, p ?-?.

Mercier A. et al, Les trois révolutions du livre. Paris : Musée des arts et métiers / Imprimerie Nationale Éditions, 2002, 511 p.

Villarmain H., Journal de 1776 à 1810, Manuscrit. Archives Départementales de la Charente, Cote J 896.